In today’s fast-paced logistics and supply chain industry, smart warehouse systems are revolutionizing storage, order fulfillment, and inventory management. Businesses are increasingly adopting smart warehouse technology to enhance efficiency, reduce operational costs, and improve accuracy. By integrating automation, AI, and data analytics, warehouses can optimize workflows, minimize errors, and improve order processing speed.

This article explores the top seven advanced technologies that are shaping the future of warehousing, offering businesses a competitive edge in a rapidly evolving market.

Table of Contents

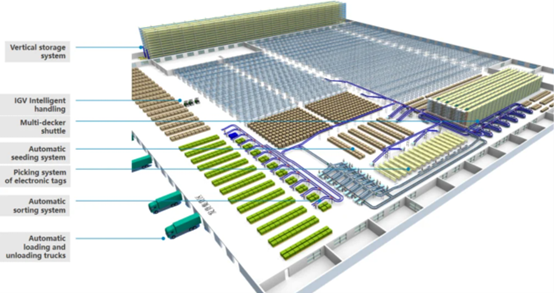

Toggle1. Vertical Storage Systems

Warehouses often face space constraints that limit their ability to scale operations efficiently. Vertical storage systems help overcome this challenge by utilizing warehouse height to maximize storage capacity, enabling better inventory organization and easier access to goods.

Vertical storage solutions, such as automated vertical lift modules and carousel systems, use mechanical lifts and rotating shelves to store and retrieve items with minimal manual handling. These systems are often integrated with smart warehouse management systems for seamless inventory tracking.

Benefits:

- Optimized space utilization – Reduces the need for warehouse expansion by making full use of vertical space.

- Increased inventory accuracy – Automated retrieval minimizes picking errors.

- Faster access to goods – Reduces retrieval time and enhances order fulfillment efficiency.

2. IGV Intelligent Handling

Intelligent Guided Vehicles (IGVs) are transforming material handling by automating the movement of goods within a smart warehouse system. Unlike traditional Automated Guided Vehicles (AGVs), IGVs use advanced navigation technologies, such as LiDAR, computer vision, and AI-driven path optimization.

IGVs move freely within the warehouse, identifying the most efficient routes to transport goods without requiring fixed pathways or infrastructure modifications. They can dynamically adjust to warehouse layouts, avoiding obstacles and optimizing workflow in real time.

Benefits:

- Flexible and scalable – Easily adaptable to changing warehouse configurations.

- Reduced labor costs – Minimizes reliance on manual handling.

- Improved safety – Prevents accidents by using smart obstacle detection.

3. Multi-Decker Shuttles

Multi-decker shuttle systems are an advanced storage and retrieval solution that significantly enhances storage density while enabling rapid access to goods.

These shuttles operate on multiple levels within a racking system, moving horizontally and vertically to retrieve items quickly. They are controlled by warehouse automation software that optimizes their movement based on real-time demand.

Benefits:

- Higher storage efficiency – Increases warehouse capacity without expanding the facility.

- Rapid order fulfillment – Reduces retrieval times for high-demand items.

- Lower operational costs – Maximizes automation while minimizing manual intervention.

4. AI & Robotic Arms in Warehousing

AI-powered robotic arms are reshaping warehouse operations by performing repetitive tasks such as picking, sorting, and palletizing with high precision.

Using machine learning and AI-driven computer vision, robotic arms can identify and handle items of varying shapes and sizes. These robots work collaboratively with human operators or as fully automated solutions.

Benefits:

- Enhanced accuracy – AI-driven recognition ensures precise sorting and handling.

- Reduced human fatigue – Automates labor-intensive tasks, improving productivity.

- Scalability – Easily integrated into existing warehouse operations.

5. Picking System with Electronic Tags

Order picking errors are a major issue in warehouses, leading to delays and customer dissatisfaction. Electronic tag-assisted picking systems use a combination of digital displays, barcode scanning, and RFID technology to enhance accuracy.

These systems guide warehouse workers or robots through optimized picking routes, displaying real-time information about item locations, quantities, and order details. Some systems also integrate augmented reality (AR) to further enhance efficiency.

Benefits:

- Minimized errors – Reduces mispicks and ensures accurate order fulfillment.

- Faster processing times – Optimized picking routes improve efficiency.

- Seamless integration with WMS – Enhances inventory tracking and analytics.

6. Automatic Sorting Systems

Sorting goods manually is time-consuming and prone to errors. Automated sorting systems streamline the classification and distribution of goods using conveyors, AI-based recognition, and robotic sorting arms.

Automated sorting solutions employ scanners, weight sensors, and robotic sorters to categorize items and direct them to appropriate storage locations or outbound shipments. Machine learning algorithms enhance sorting accuracy over time.

Benefits:

- Faster and more efficient sorting – Reduces bottlenecks in distribution.

- Cost savings – Reduces the need for manual labor.

- Improved accuracy – Minimizes shipment errors and enhances customer satisfaction.

7. Automatic Loading and Unloading Platform

Loading and unloading platforms are one of the most labor-intensive processes in warehousing. Automated loading and unloading systems integrate robotics and conveyor belts to expedite this process.

Using smart conveyor systems and robotic arms, goods are loaded onto or unloaded from trucks with minimal manual intervention. These systems work seamlessly with warehouse automation platforms to ensure smooth logistics operations.

Benefits:

- Reduced loading/unloading time – Accelerates supply chain processes.

- Lower labor dependency – Reduces workforce requirements for repetitive tasks.

- Improved transportation efficiency – Minimizes truck idle time, optimizing logistics.

Siwun’s Smart Warehousing Solutions

Siwun has been a pioneer in intelligent logistics systems and customized specialty vehicle solutions. With extensive experience in industries such as express services, e-commerce, air transportation, warehouse management, tobacco distribution, and industrial automation, Siwun has become a trusted equipment supplier.

Siwun’s smart warehousing solutions integrate the latest AI-driven automation, advanced robotics, and warehouse management software to optimize operations. We provide:

- Tailored warehouse automation systems designed to enhance efficiency and scalability.

- Comprehensive logistics solutions, including data warehousing and business intelligence, to improve supply chain visibility and decision-making.

- State-of-the-art handling equipment, ensuring seamless warehouse operations with minimal human intervention.

With a strong commitment to innovation and customer success, Siwun Logistics continues to empower businesses worldwide with smart warehousing technologies that drive efficiency, accuracy, and productivity.

Conclusion

Adopting smart warehouse technology is essential for businesses aiming to remain competitive in logistics and supply chain management. From AI-driven automation to intelligent storage solutions, these seven technologies significantly enhance efficiency, accuracy, and productivity. By leveraging these innovations, companies can transform their warehouse operations, optimize inventory management, and achieve sustainable growth in an increasingly digitalized industry.